Fish & Seafood X-Ray Reclaim Services

Our x-ray inspection systems are specifically designed to ensure the safety and quality of a wide variety of packaged meat products commonly found in supermarkets. Examples include sausages, steaks, burgers, cold meats, ground meat, canned meat and pate. In addition to detecting metal contaminants in meat products, our end-of-line x-ray systems can detect glass, mineral stone and calcified bone, as well as help meat manufacturers maximize overall line efficiency and avoid product recalls by simultaneously measuring weight, inspecting product seals and counting components.

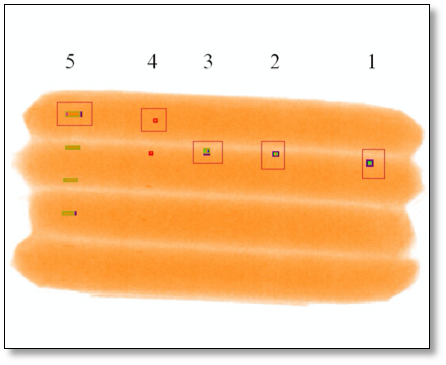

This newly-available detector technology, first proven in the poultry industry for superior bone detection, captures a greater amount of information about the product being inspected and produces more detailed x-ray images to deliver the most accurate contaminant detection in the industry. With PXT™ technology, seafood processors can detect the smallest of bone fragments, ensuring safe products for their consumers and strengthening brand protection.

Our machines can even inspect challenging packaging like metal cans with pull-tabs or lids, a tuna can for example. With Eagle’s advanced software, SimulTask™ PRO, density variation can be configured making it so that the system ignores the pull tab and only looks for the contaminant. Eagle x-rays inspect a wide range of chilled, frozen, and canned/preserved fish and seafood products like fish spread in tubes or glass jars, as well as bulk fish and seafood, ready meals, tinned tuna or herrings, and formed-style fish fingers or cakes.

In addition to detecting contaminants, our x-ray machines simultaneously check fill level, measure mass, inspect seals for trapped product and contaminants, count components, and detect missing, partial, and crushed products. Eagle also understands that the hygienic design of x-ray inspection systems is critical in order to prevent the growth and spread of biological contamination in fish and seafood manufacturing plants. For this reason, all our x-ray systems fulfill international sanitary design guidelines and are easy to clean.

Plan Automation offers a range of x-ray solutions to inspect incoming meat for sausage production, processed sausages and packaged sausages.

Plan Automation offers a range of x-ray solutions to inspect incoming meat for sausage production, processed sausages and packaged sausages. An accurate and fast standardization process is vital for manufacturers of minced meat products. We offer end of line x-ray systems for detection of metal, glass, mineral stone, calcified bone and high-density plastics and rubber contaminants, ensuring products are safe for consumption and the correct weight. Machines are capable of inspecting ground meat in a variety of packaging types, including chubs.

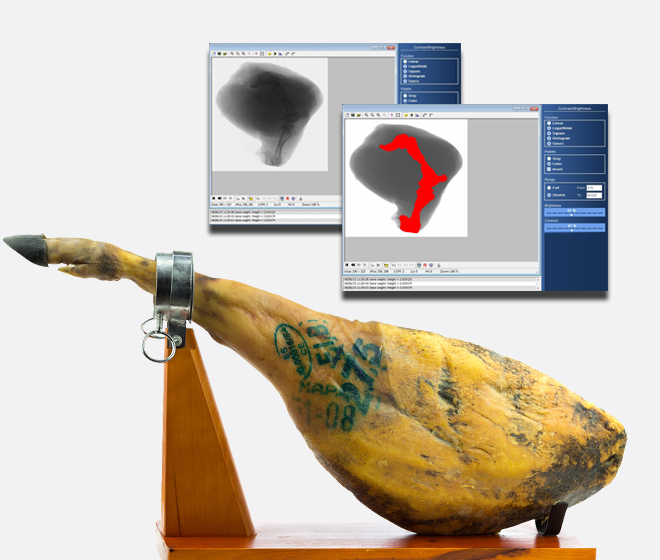

An accurate and fast standardization process is vital for manufacturers of minced meat products. We offer end of line x-ray systems for detection of metal, glass, mineral stone, calcified bone and high-density plastics and rubber contaminants, ensuring products are safe for consumption and the correct weight. Machines are capable of inspecting ground meat in a variety of packaging types, including chubs. At our Bolton facility, we provide x-ray inspection food solutions which are capable of inspecting complete sections of meat with the bone in, such as hams.

At our Bolton facility, we provide x-ray inspection food solutions which are capable of inspecting complete sections of meat with the bone in, such as hams.